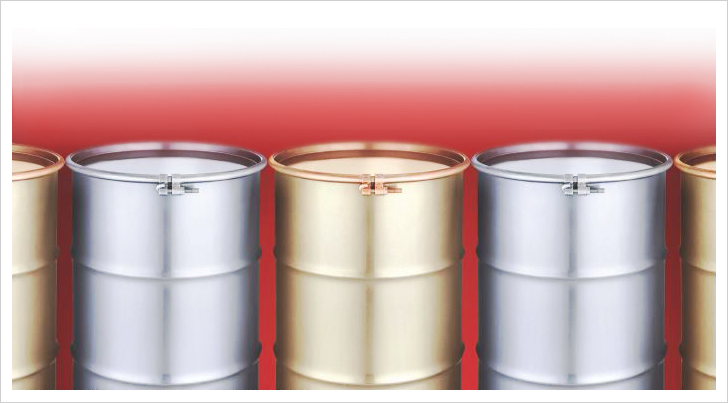

Drum Packaging

- Packaging Business Division

- The OJC Packaging Division is a comprehensive can production maker that manufactures cans and 200L steel drums for general industrial use and food products using eco-cans of various sizes. We provide one-stop service from ordering, to production, and delivery in Gyeongin / Jungbu / Honam regions by constructing a small quantity batch logistics system and a network system for each region. We also strive to provide products that satisfy our customer’s needs by using automated production facilities.

- OJC drums are safe and versatile

- Drums are made of cold rolled steel, with a 3-piece shape joining the body, the upper, and lower plates. They are divided into closed types and open types, depending on the combination of the main body and the upper and lower plates. Additional manufacturing processes such as inner coating, cleaning and external painting are done to customers' specifications. Since we have the only drum cleaning line in Korea, we produce products that are suitable for packaging the content that needs to be cleaned. Moreover, our inner coating products are also designed with quality know-how; even water-soluble products and acidic products can be packed.

- Product Specifications

-

By grade SL grade NL grade NN grade LL grade LM grade MM grade HH grade COIL thickness (mm) Main Body 0.8 0.9 0.9 1.0 1.0 1.2 1.6 Upper and Lower Plates 1.0 1.0 0.9 1.0 1.2 1.2 1.6 ※ Inner Diameter 568mm x Height 890mm x Capacity 200L

- Epoxy-Coated Drums

- Suitable for water-soluble raw materials or cold-rolled steel sheets. as well as acid-based products.

- · Main Coating Ingredients : phenol epoxy resin

- · Strengths : adhesiveness, chemical resistance, water resistance, excellent electrical properties

- · Packaging Materials: paint, silicone, medicines, etc.

- Cleaning Drums

- Containers dedicated to packaging materials sensitive to foreign substances.

- Uses a solvent that has the most efficient cleaning ability (developed by HMC & KCC)

- The cleaning process is exclusive to OJC, and is the only one of its kind in Korea

- · Strengths: It eliminates oil and foreign materials in drums, and maintains maximum

levels of cleanliness. - · Packaging materials: semiconductors, automotive paints, etc.

- Drum Plugs

- Steel plugs

- · Trivalent chromium plating on cold-rolled steel sheets

- · Satisfies WHO regulations (March 2015), compliant with ROSH

- · 4 zeros : zero toxins, carcinogens, allergens, or corrosive properties

- Zinc Alloy Plugs

- · Since they are less corrosive, they do not rust or deteriorate

- · They are not affected by the external environment after packaging

- Stainless Plugs

- · Able to withstand corrosion.